Polyethylene (PE) Sleeves for D.I. Pipes

Used in conjunction with Ductile Iron pipes and fittings to provide corrosion protection (especially in aggressive soils). Polyethylene (PE) Sleevings (otherwise known as wrappings or encasements) are manufactured with virgin LDPE as main ingredient and incorporate UV stabilizer and colorants.

PE Sleeves are the easiest, most economical and most effective method of ensuring Ductile Iron pipe protection. They are used to provide a non-bonded film covering to prevent the iron pipe from coming into direct contact with the surrounding soil. This reduces the electrolyte available to support any corrosion activity leaving only the moisture that might be present in the thin annular space between the pipe and polyethylene sleeve.

In effect, although some moisture with the corrosive characteristics of the surrounding soil may become entrapped inside the sleeve, the available dissolved oxygen supply beneath the wrap is soon reduced and the oxidation process inhibited long before any real damage occurs. Trapped water soon enters a state of stagnant equilibrium where a uniform environment exists around the pipe.

To be effective, only the best quality sleevings should be used. For this reason, Qatar National Plastic Factory PE sleeves are manufactured to the highest standards being rot-proof, to inhibit biodegradation or chemical decomposition.

PE Sleeves Products

Qplast PE Sleeves are available in different colours depending on their utilisation. There is a wide variety of product available. We ensure a supply of stocked sleeves for potable water and drainage as follows:

Potable Water Network Dl Pipes

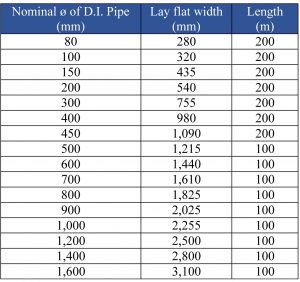

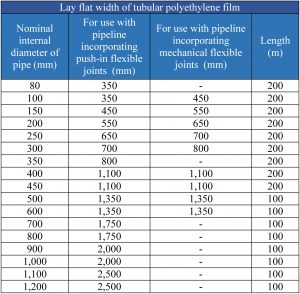

Standard: ISO 8180

Thickness: 225±25 microns

Colour: Blue RAL 5005

UV protection: Enabled

Above sizes specified by KAHRAMAA water department

Drainage Network Dl Pipes

Standard: BS 6076

Thickness: 200-250 microns

Colour: Black RAL 9004

UV protection: Enabled

Above sizes comply with QCS Section 8 Part 3, 3.7.5 requirements for sleeves for drainage networks.

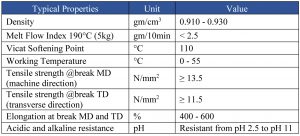

Tested Values of PE Sleeves

The tested values of our sleeves are as follows:

Polyethylene (PE) Sheets and Films

LDPE Construction Sheet

Low Density Polyethylene (LDPE) Films are manufactured using virgin low density film grade polyethylene in accordance with BS 2782 and BS 3012.

Generally, sheets are transparent; however, we also produce coloured or tinted sheets as required. LDPE sheets have a wide range of applications including as water vapour barriers in the construction of roads, multi-storey buildings, farms and for the protection of goods and installations.

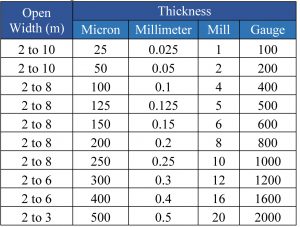

The following sizes are available and classified according to sheet thickness:

LDPE Green House Films

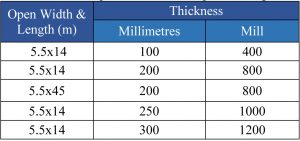

Greenhouse films are manufactured using virgin low-density polyethylene (LDPE). Especially important is the additional UV stabilisation required as the films are constantly exposed to sunlight. Our films contain 3% to 5% UV-stabilizer to ensure the stability of films in sunlight. The films are manufactured in light green colour or as required. Our Films are also used to control crop conditions and exposure in agricultural farms.

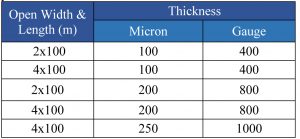

LDPE Agricultural Mulch Films

Agricultural Mulch films are manufactured using virgin low-density polyethylene (LDPE). These films are available in black and transparent with UV protection as standard. These films are used in agricultural projects as a deterrent against sunlight. Mulch films are used to control soil temperature, limit weed growth, prevent moisture loss, and improve crop yield.

Width and length are customizable.