COMPANY PROFILE

Qatar National Plastic Factory W.L.L. (QNPF) is leading manufacturer of:

- PVC Pipes and Fittings;

- PE Pipes;

- PE Construction Sheets and Warning Tapes; and

- Cable Protection Tiles (PE).

Founded in 1977 (and one of the oldest industrial manufacturers in Qatar), Qatar National Plastic is now completing a QAR70 million programme of investment to modernise and expand the production range and capacity at our 22,000sqm facility in Doha-New Industrial Area. We are adding a complete range of fittings (drainage, soil & waste, pressure, conduits, spacers, etc) to our Qplast product line, manufactured to the highest international specifications and available by Q4, 2018.

We are fully approved for the sale of all products in Qatar with a 41-year record of success. We manufacture PVC pipes from 20mm to 630mm; PE pipes from 16mm to 800mm.

Our extensive indoor storage of 9,400m2 at the factory, supplemented by additional offsite storage enables us to stock large quantities of pipes, fittings and other products away from sunlight, to give the best conditions and to enable continuous delivery.

In recent years, our general philosophy has changed. We are investing in the best technology production equipment to improve efficiency. We are introducing new technology to create a healthier water distribution network. We use no lead (Pb) in our products and we recycle as much as possible. To help improve the Qatari environment,we purchase between 2,400 and 2,700MT of Qatari waste plastic for reuse in our warning tile production, but we use none of this waste in our pipe production. We have recently terminated plastic bag production due to environmental problems, their use is causing; and we are introducing energy saving measures into our factory to reduce our pollution and carbon footprint.

Qatar National Plastic Factory is an Al Attiya family company founded by HE Brigadier Mohammed Al Attiya and still owned by his descendants and family.

u-PVC AND c-PVC pipes

Qatar National Plastic has a total capacity to manufacture more than 3,000MT per month of PVC pipe. We manufacture and stock a range of sizes of pipe (20mm to 630mm) as follows:

uPVC High Pressure Pipes (BSEN 1452, BS 3505, DIN 8062, ASTM D 1785)

uPVC Soil & Waste Pipes (BSEN 1329, prev. BS 5255);

uPVC Underground Drainage Pipes (BSEN 1401 prev. BS 4660, including perforated);

uPVC Drain, Waste & Vent Pipes (ASNZS1260-2017 and ASTM D 2665);

uPVC Electrical Conduits (BS 4607 and NEMA Standard);

uPVC Telephone & Electrical Ducts (Kahramaa, Ashghal, UGN, QAF, MOI-SSD, CRA, Vodafone and Ooredoo Specification, BS 4607).

Addition to the above, Qatar National Plastic is able to manufacture special pipes for custom orders, for example u-PVC perforated drainage pipes are manufactured on request according to QCS and international standards such as BSEN 1401.

Innovation: In Q4 2018, we will become the first company to introduce the new ChemART® uPVC technology with greater chemical resistance and increased microbial growth prevention for uPVC pipes. This pipe also have improved flow. This PVC pipe is completely resistant to chlorine dioxide chemical attack and a cost effective solution for drinking water applications above 50mm diameter.

PVC Pipe Fittings.

The Injection Moulding Division began operating in 2016 and by Q4 2018 will have expanded to a planned capacity of 620MT per month. This will double in 2019 to reach 1,500 MT per month.

We are currently producing Qplast u-PVC fittings for use with BSEN 1329 and BSEN 1401 pipes for underground and above ground drainage systems. During 2019, this range will expand to include high pressure pipe fittings confirming to BS 3505 and DIN 8062, as well as electrical conduit fittings confirming to BS 4607 and other relevant European norms.

This production is in addition to our in-house fabrication of various u-PVC electrical duct accessories including bends and welded fittings and our range of electrical duct spacers designed particularly for the Qatari environment (interlocking HDPE Ducts spacers).

For those that require uPVC fittings and pipes with an European brand, we continue to supply:

High Pressure Pipe Fittings from EFFAST (Italy); and

Drainage Pipe Fittings from REDI (Italy).

Qatar National Plastic also manufactures both Effast and Redi pipes under license from these European manufacturers for sale with the fittings.

HDPE pipes and fittings.

Qatar National Plastic has a monthly production capacity of HDPE pipe of more than 1,000MT. Our pipes are manufactured to conform to both European and ISO standards. Pressure pipe conforming to ISO 4427, ISO 4437, DIN 8074 and 12201, drainage pipes confirming BSEN 1519, BSEN 12666. Addition, we produce HDPE ducts in accordance with the requirements of the various Qatari standards including Kahramaa, ITS, QNBN, Vodafone.

We manufacture on demand HDPE perforated pipes (half and full) in accordance with both ISO 4427 and BSEN 12666.

HDPE fittings are supplied from PLASTITALIA (Italy) or as fabricated internally.

Polyethylene Tiles (for buried cable warnings)

The PE Tile extrusion is carried our on 2 machines with a combined monthly capacity of 470MT. Qatar National Plastic products are approved by all major Qatari utilities and users such as Kahramaa and Qatar Petroleum (QP) with tile thicknesses of 6mm, 8mm and 12mm and a variety of widths. Tiles are supplied with joining pegs.

Polyethylene sheet, warning tapes and sleeves (for DI pipes).

Production capacity for films and sheet with a thickness of 0.5mm and below is more than 500MT per month. We produce the following:

V treated greenhouse films;

agricultural mulch films;

Polyethylene Sleevings for Ductile Iron Pipes (UV Treated);

Polyethylene Sheets (Up to 2000 Gauge)

Polyethylene Trench Marker Tapes and warning tapes including;

- KAHRAMAA (water & electrical),

- Ashghal (drainage);

- Telecom;

- Street Lighting;

- Intelligent Transportation System;

- UGN;

- Ooredoo;

- Vodafone, etc.

We already hold the approval from all government end users for our sheet and film products.

Qatar National Plastic Quality Control

Quality can never be taken for granted. It requires constant commitment.

Since 2016, Qatar National Plastic has invested over QAR 2.1 million in the latest quality control test equipment and training. We believe that strict adherence to quality standards is critical: from raw material selection through to the final manufactured product. In addition, this commitment must be reflected in storage, transport and installation.

At present, the Qatari market relies for the most part on a third party test certificate to approve pipe manufacturers. There is little checking of factory facilities or actual production. This has led to a situation where companies do not invest in the necessary test equipment normally required by regulators, utilities and contractors, nor do they adhere to the chemical composition of the product necessary to comply with the relevant standard. The heavy metal Lead (Pb) is frequently used in the stabiliser, although this is in fact banned in Qatar.

Qatar National Plastic’s “Qplast” brand is produced without compromise.

The product is lead (Pb) free.

Pipes and fittings are manufactured according to standard.

All batches are routinely tested according to standard.

No contaminated materials are used.

Testing is done with the latest European equipment, per standard.

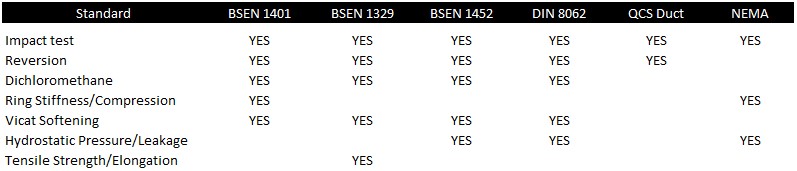

In accordance with international standards the following tests must routinely be carried out on particular pipe production batches to ensure quality:

In addition to the above tests, there are tests performed on the raw materials (eg: bulk density, volatile content, ash content, etc.) as well as product tests performed with less regularity such as long term pressure, ash content, long term vicat softening, opacity, etc.

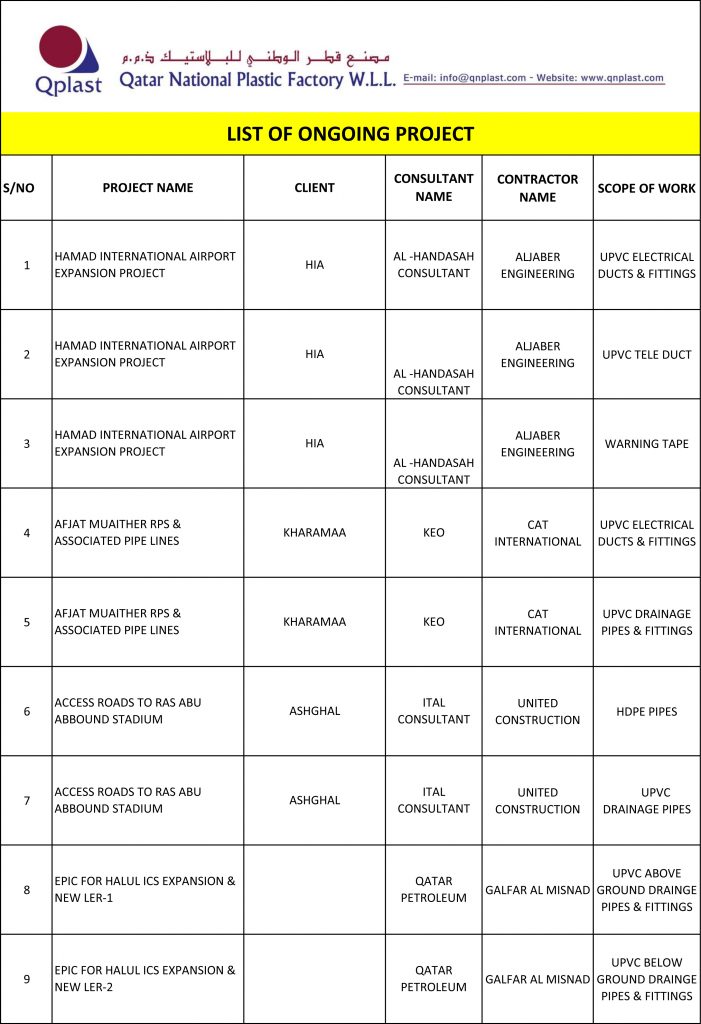

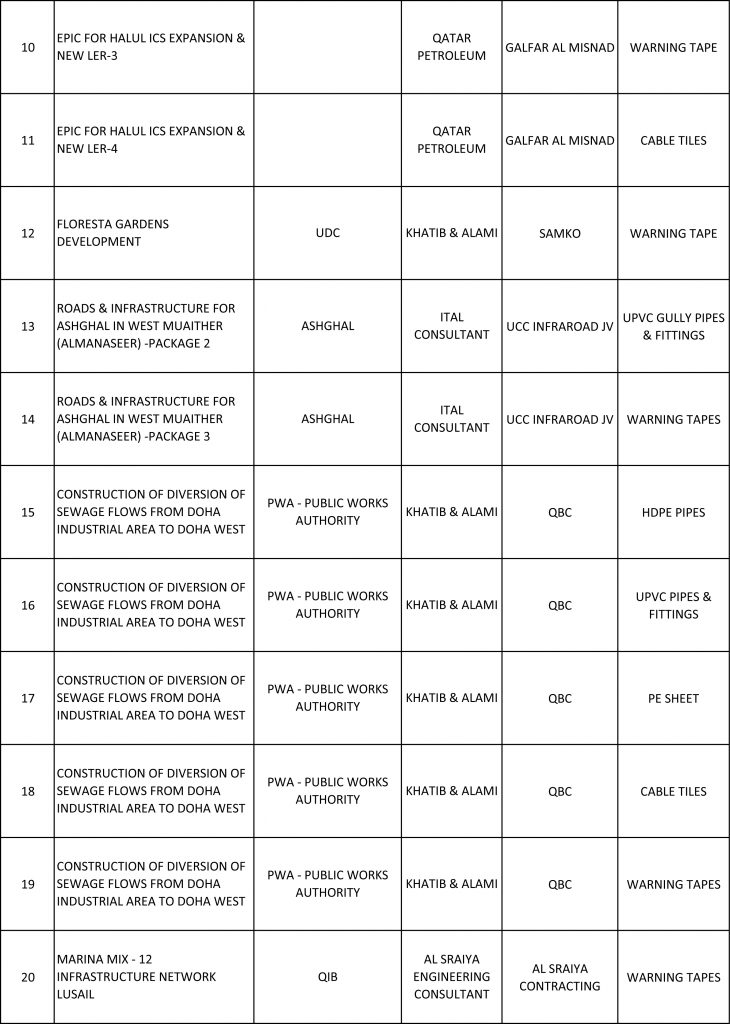

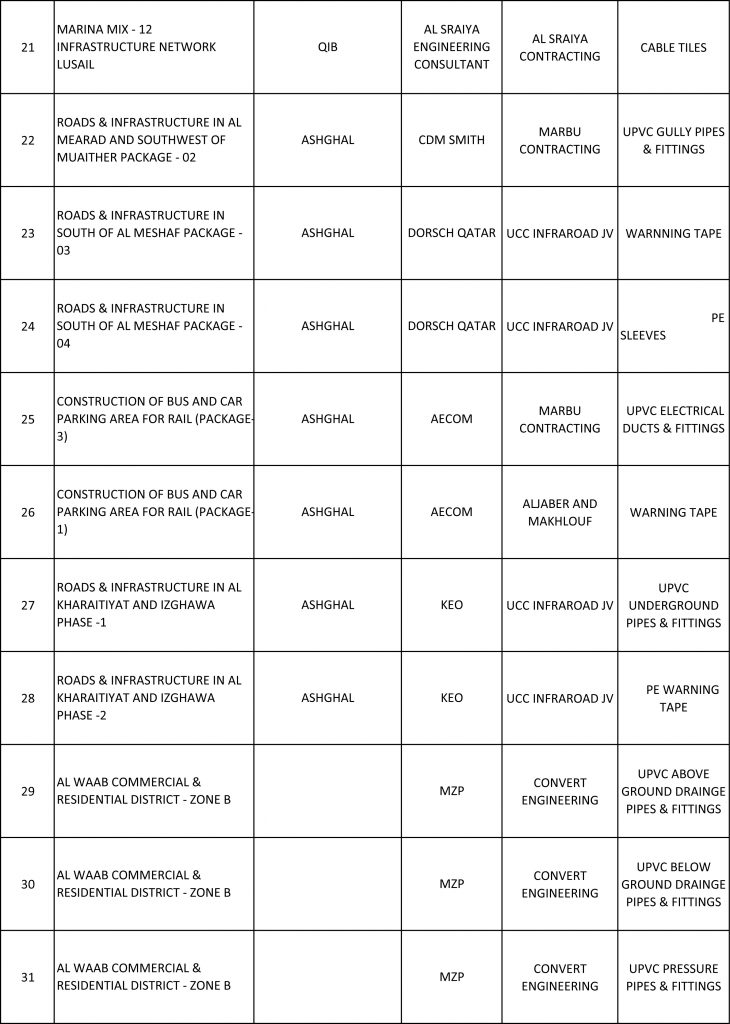

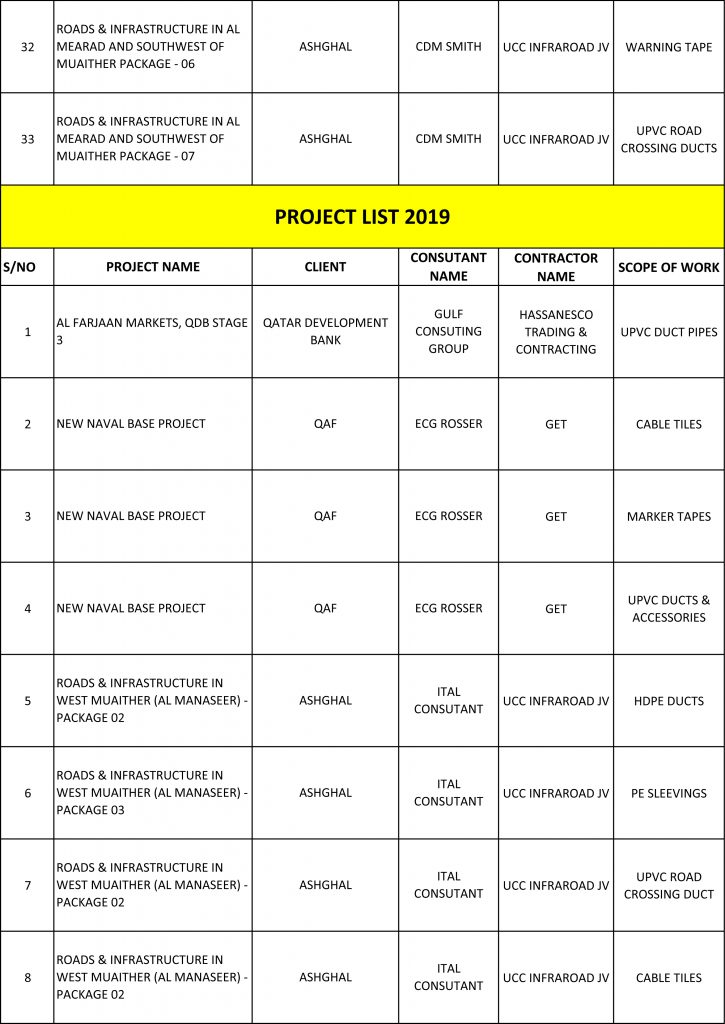

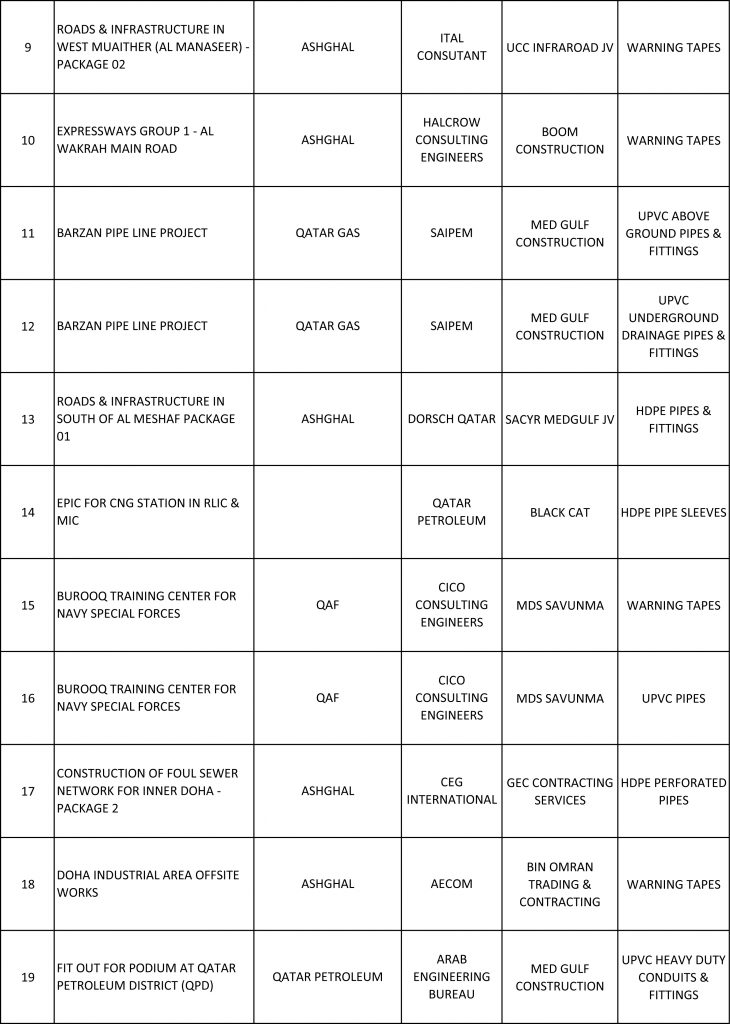

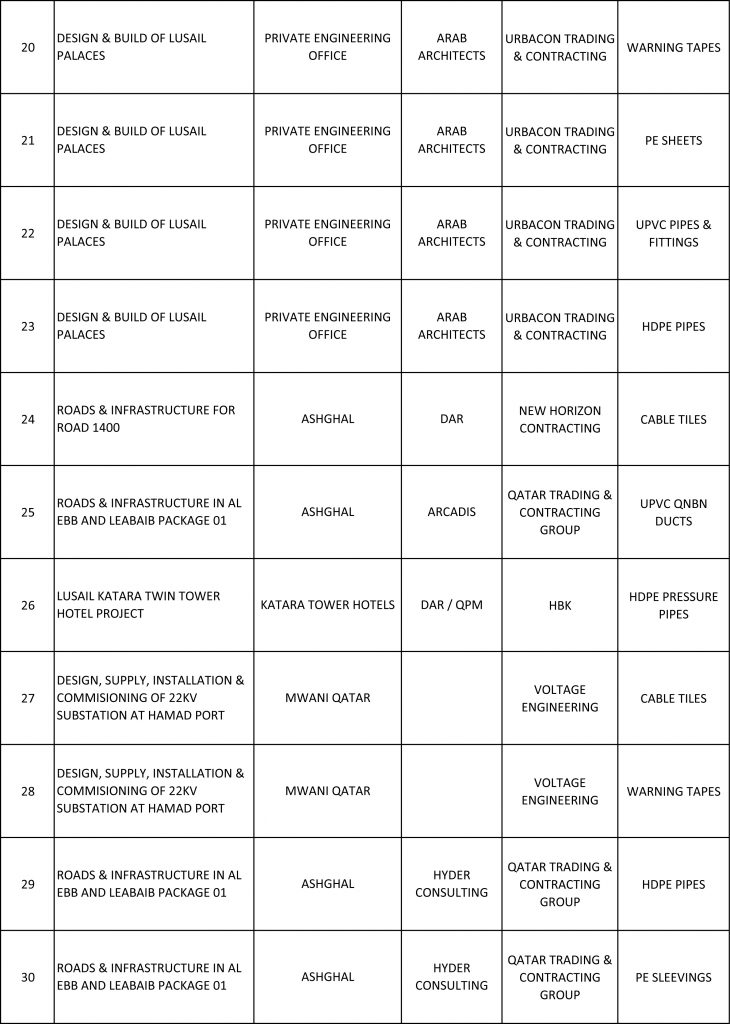

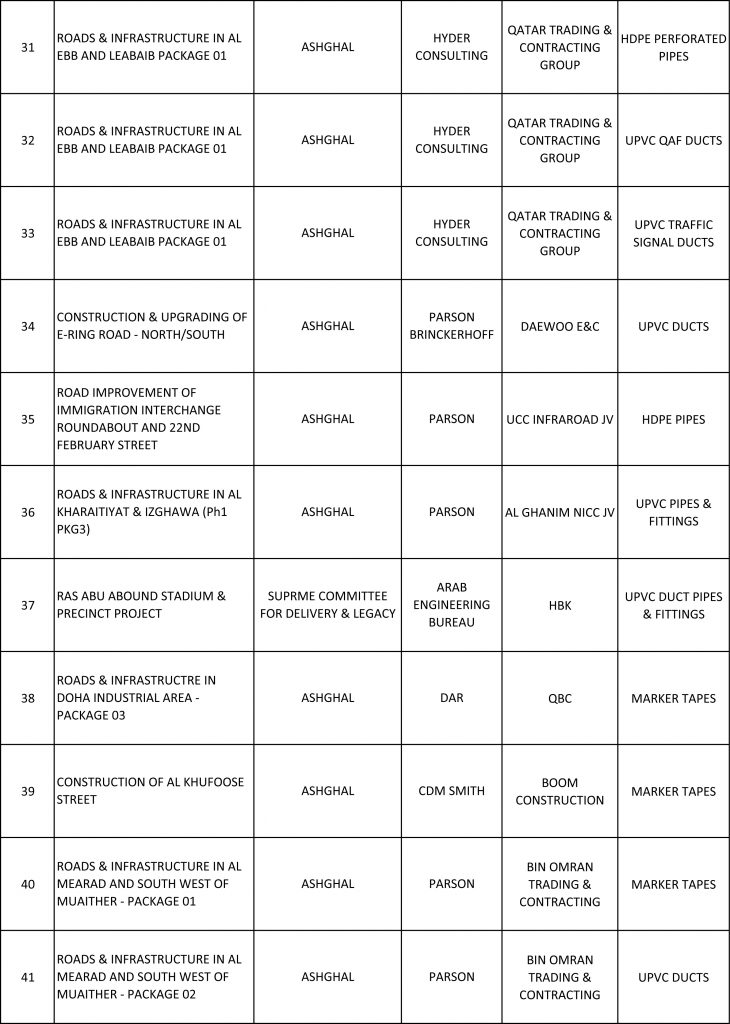

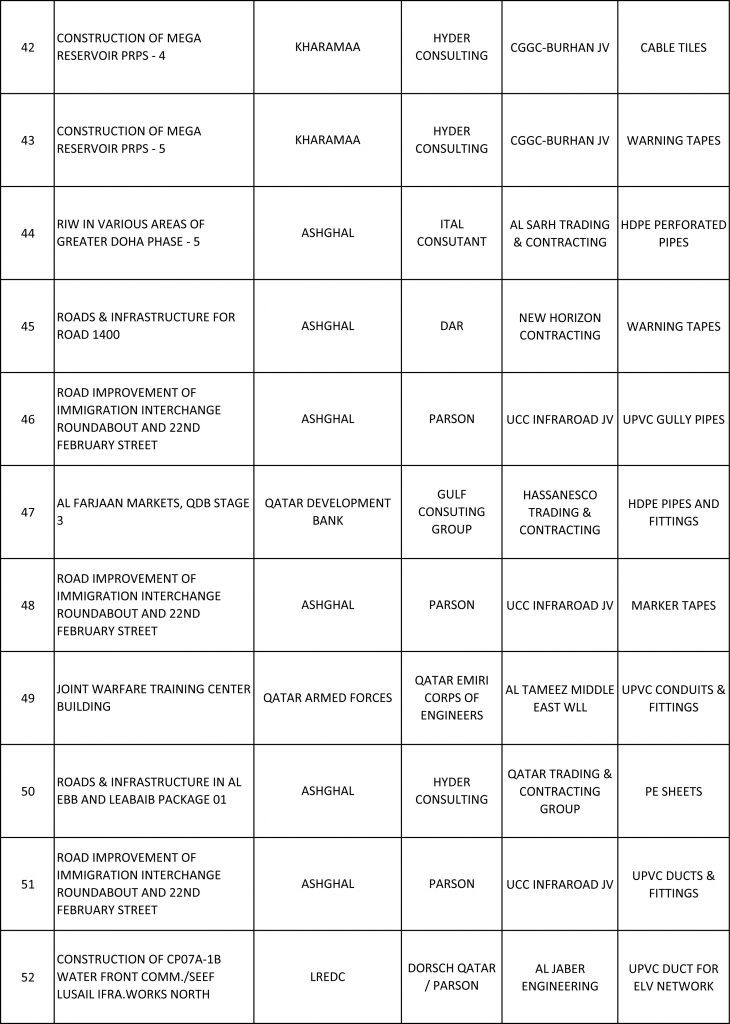

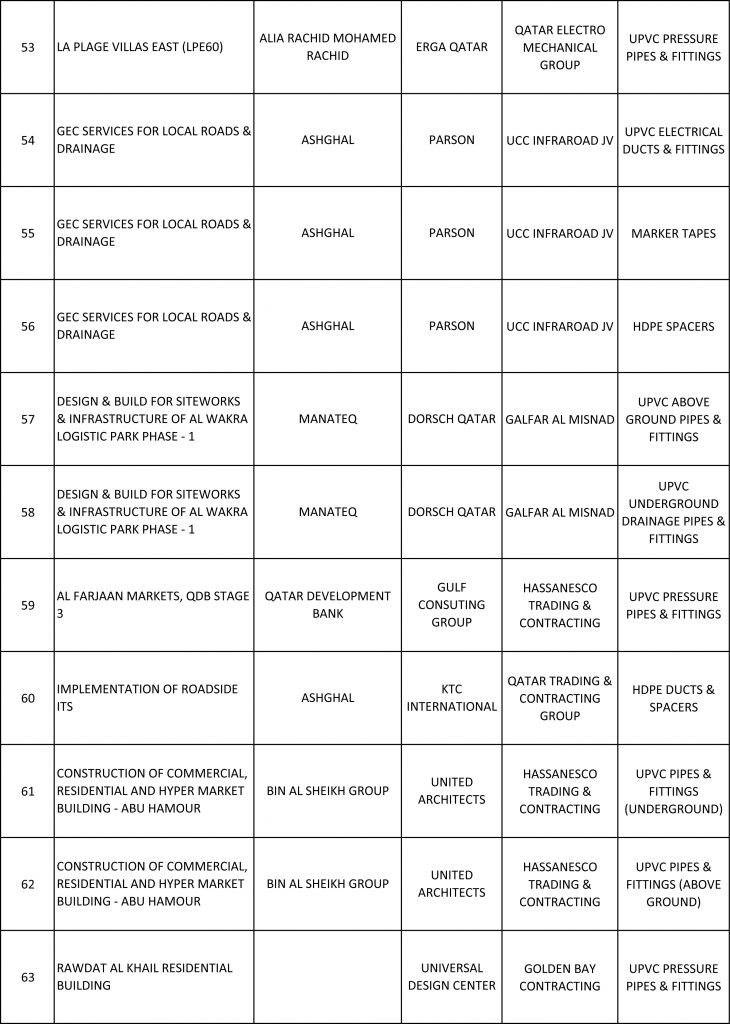

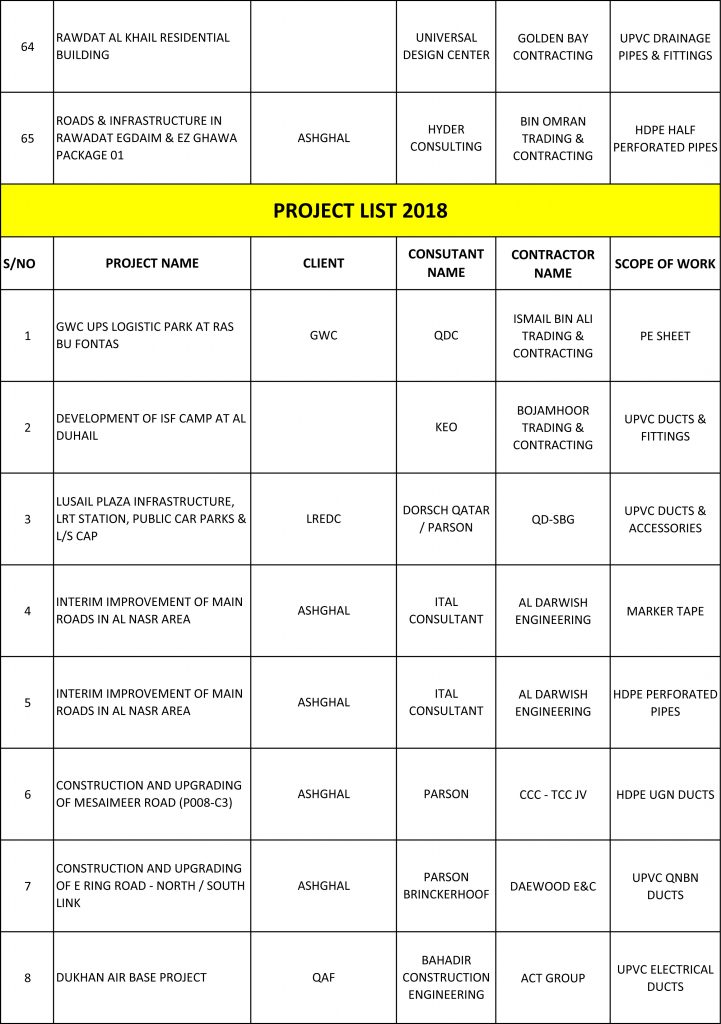

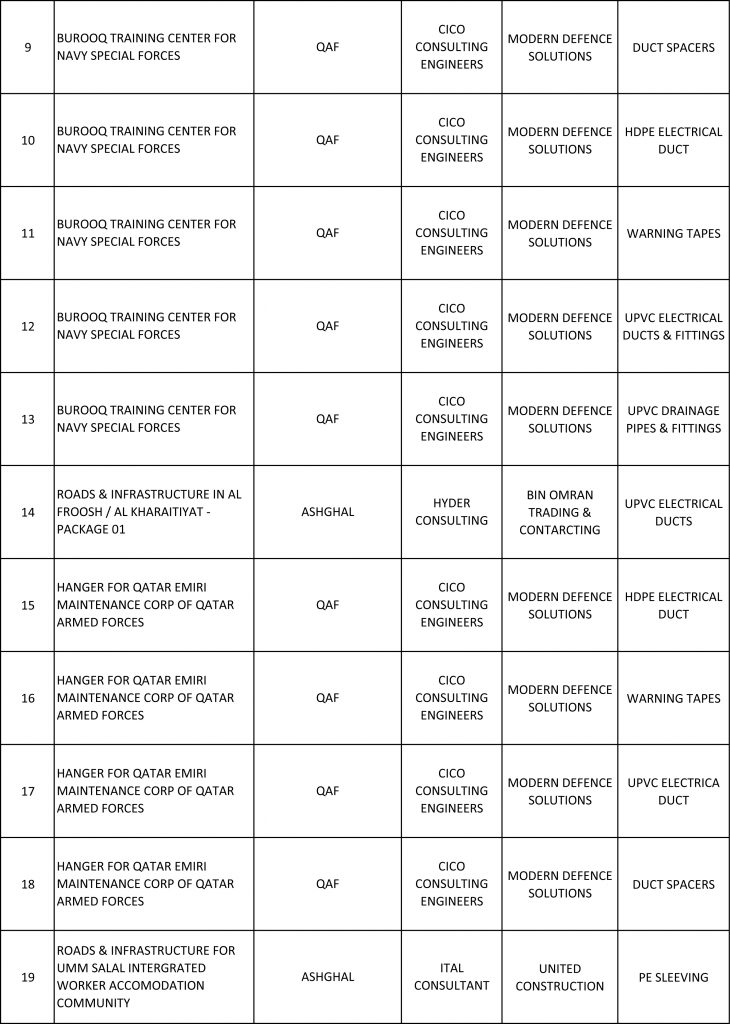

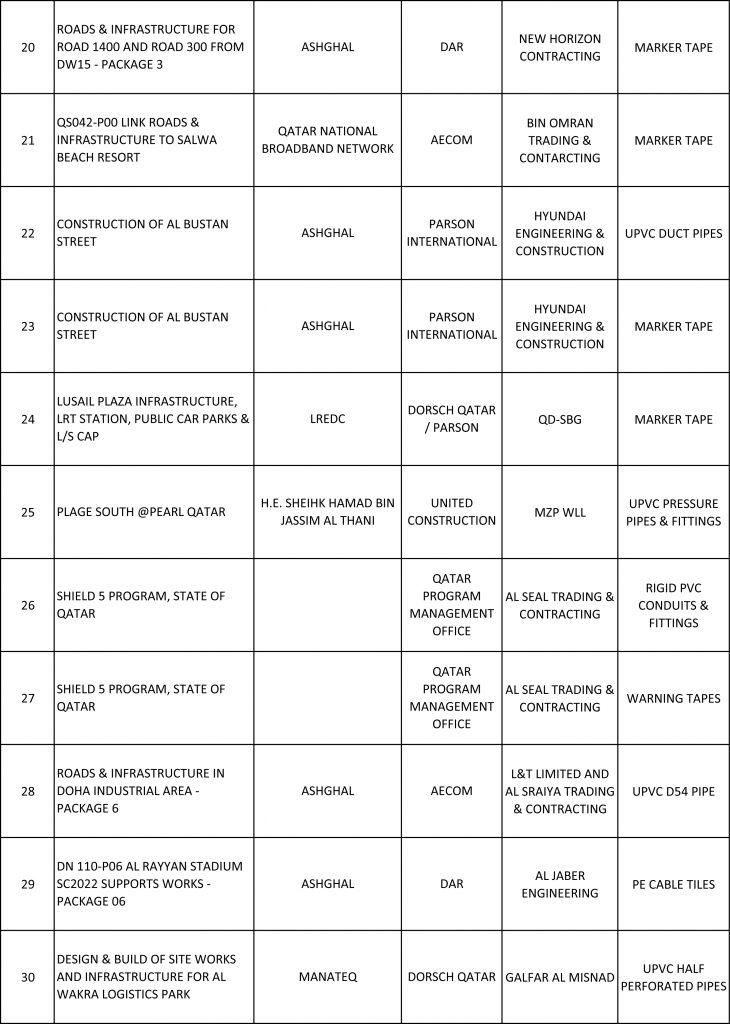

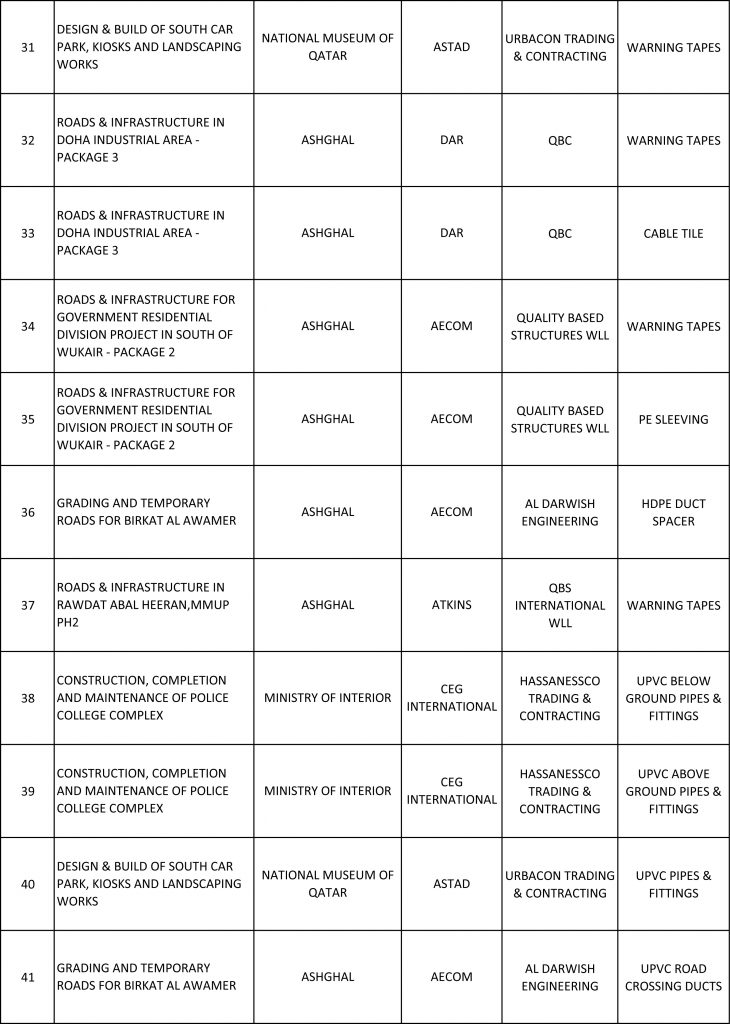

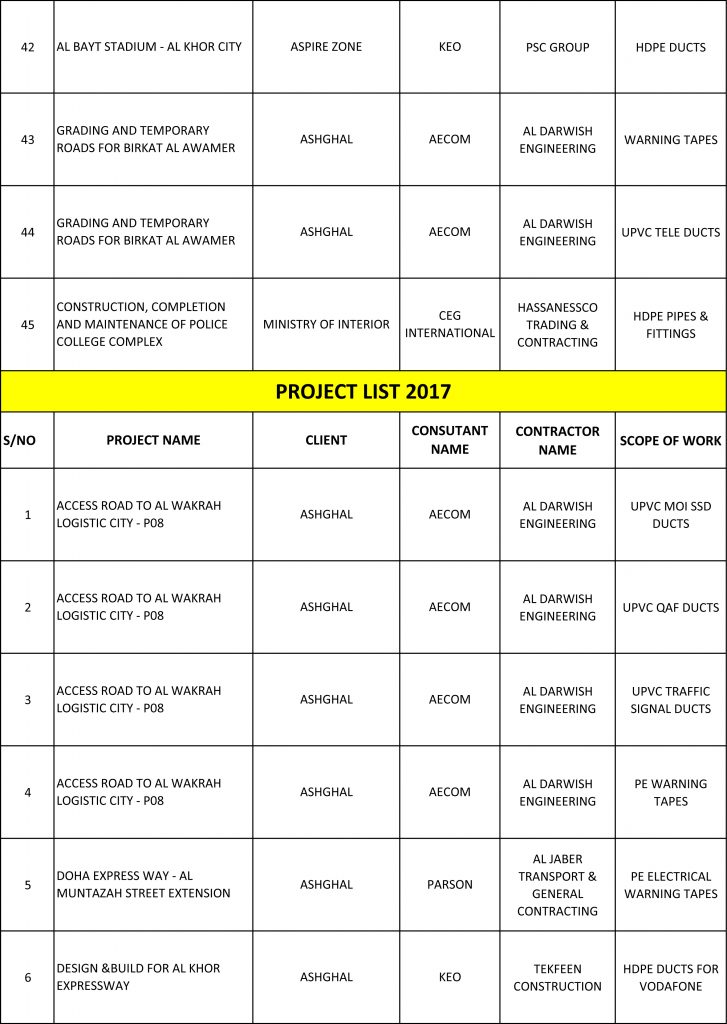

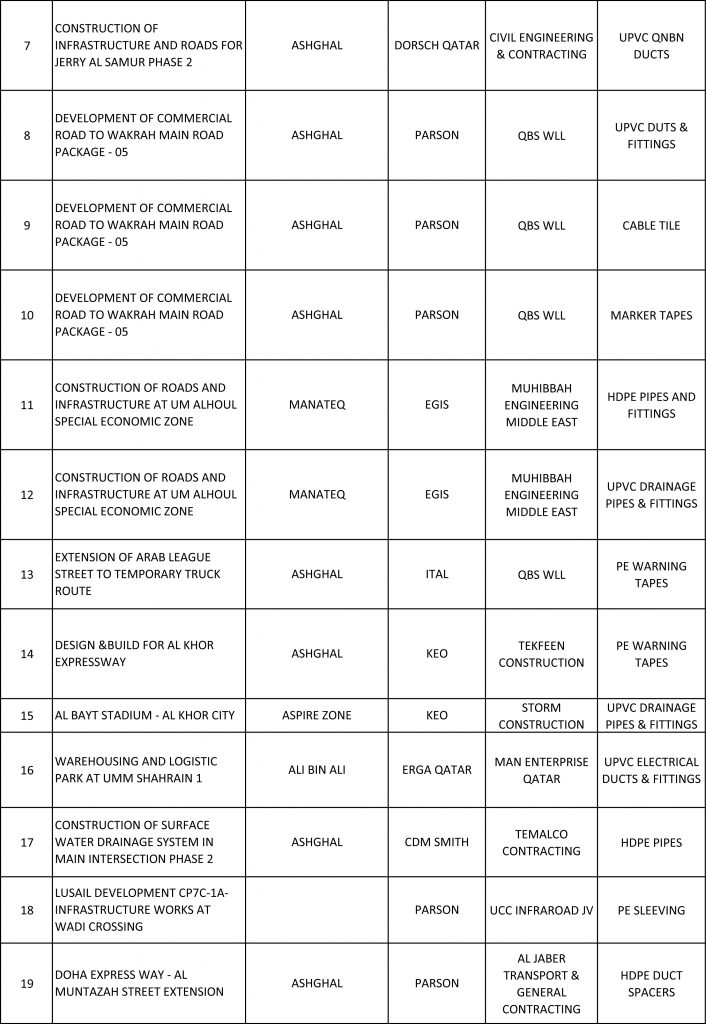

PROJECT LIST

NOTE:

Technical submittal should be address to the concerned person, kindly email your project details, quotation number of the requested submittal

and other other required documents needed to the following email address:

tso@qnplast.com / tsc@qnplast.com